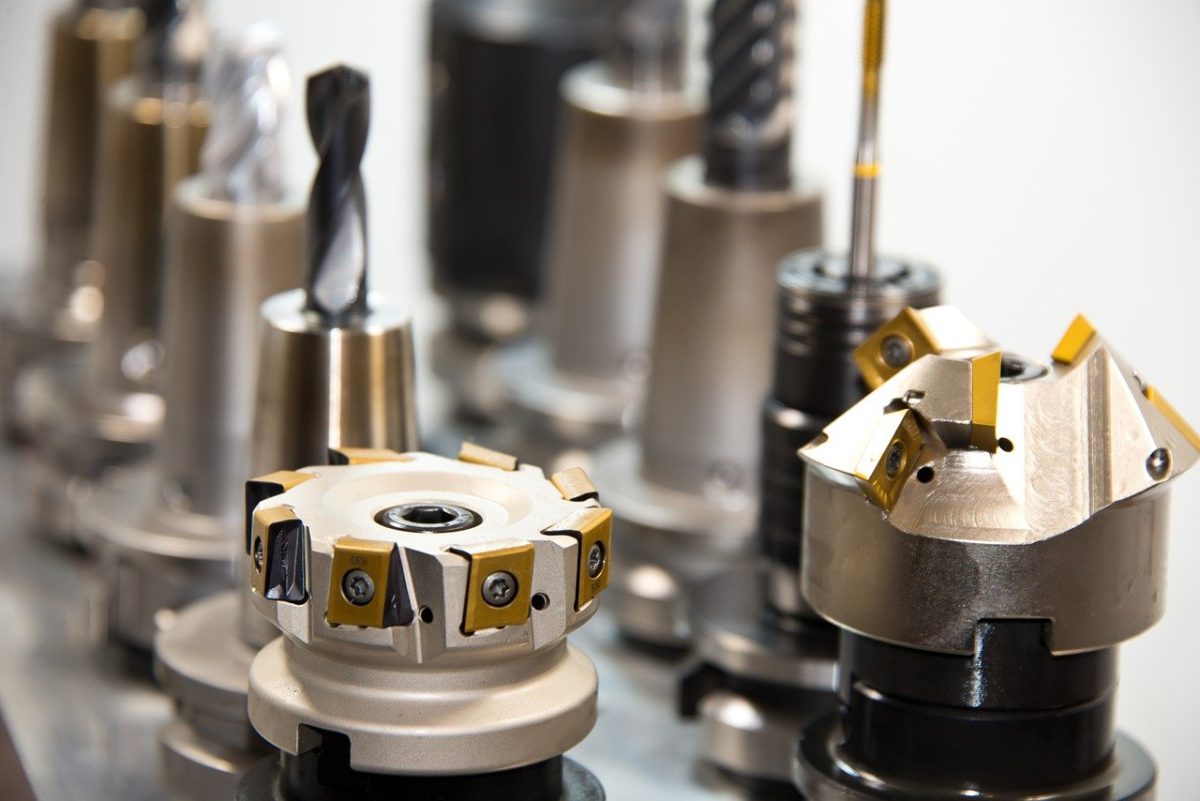

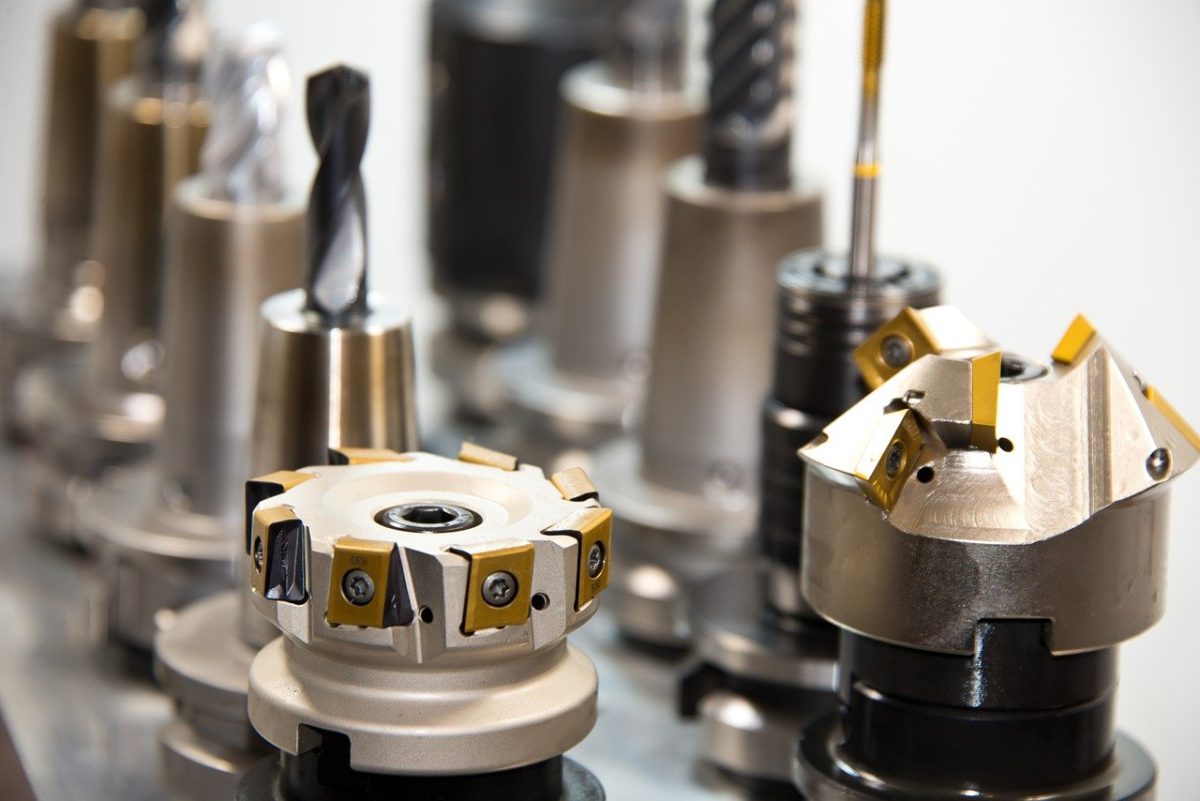

Milling machines were invented in the early 19th century and have since become indispensable machines in machine shops . These machines are capable of producing parts by chip removal thanks to the help of the cutting tool: the milling cutter . But for the operations carried out by this machine to be of quality, all the components of the equipment must be; thus, the bed of the milling machine, the cutting tool, the head, the plate and other parts must meet a series of technical specifications.

Features of milling machines

Milling machines are some of the most versatile machines in workshops. They are capable of performing multiple machining operations , but also accept a large number of materials . Here we find metals , wood , steel, cast iron and synthetic materials; it is also possible to find pieces with different surfaces: concave, convex, flat, curved , jagged , etc. And, in addition, the pieces that have been worked on a milling machine can be subjected to other processes such as roughing and refining .

Milling machines can be classified in two ways: according to the orientation of the tool and according to the number of axes of the same. According to the orientation of the milling cutter , the most common models of milling machines are horizontal , vertical and universal . The horizontal milling machine is characterized by using cylindrical milling cutters and being able to carry out grooving work. For its part, the vertical milling machine allows the work table to move up and down, which makes it possible for the depth of cut to be greater. This type of milling machines can be divided intofixed bench and turret or console. Lastly, universal milling machines , if used with the proper attachment tools, can be converted to vertical; these milling machines are characterized in that the ram or carriage can move from front to back and vice versa.

Due to the number of axes , these machines can be three , four and five axes, which are the most complex milling machines, as they can perform much more precise work. Generally, the bed of the conventional milling machine can only move along the X, Y and Z axes .

Milling machine parts

Although there are different types of milling machines, as you have already seen, they all have common elements . Here we find:

- Milling bed : the entire structure of the machine is supported on this.

- Body : also called frame, it is placed on the bed of the milling machine.

- Console : this part moves vertically on the tracks and is attached to the machine.

- Transverse carriage : serves as a support for the table.

- Milling machine table : the piece to be worked on is placed on it.

- Bridge : It is placed on the frame. It has lunettes as a support for the tool holder.

- Tool axis .

- CPU – unit that controls the machine process (common in CNC milling machines ).

- Handwheel : allows movement on the X, Y and Z axes.

- Motor : part that turns the cutter.

- Column.

- Torpedo.

- Crank.

- Spindle – Allows you to move the cutting tool vertically into place.

What is the bed of the milling machine?

Perhaps one of the most neglected parts of the milling machine is the bed . The bed, in general, is a fixed structural system, common to all machine tools, characterized by its rigidity . This is, in fact, one of the most requested qualities of machine tools. The benches are present in all machine tools due to the deformations of the structure that serve to condition the precision of the machining. For example, in machine tools, the deformation of the structure has to be less than the desired precision.

And it is that, for example, a machine such as a milling machine , which regardless of the type and model works at high cutting speeds to remove chips , requires a solid structure. The main function of the bed in the milling machine is to facilitate machining : that the pieces can be worked easily, with the minimum of vibrations and, of course, that the piece does not deform, but is very precise .

bed milling machines

We have already anticipated that all machine tools have a bed and also that there is a type of milling machine that is characterized by this part of the machine. This is the bed milling machine , also called fixed bench milling machine . In this machine, which is vertical, the tool spindle is positioned in such a way that the cutter can rotate on its horizontal axis and, at the same time, perpendicular to the part to be machined. On these mills the bench can be adjusted to handle parts easily.

It receives this name because it is precisely the table that can move, and the procedures are highly precise . Here the mill head will move up and down along the length of the column; also the worktable can withstand heavy loads and the milling cutter can perform high-precision work.