The universal milling machine service is associated with multiple sectors of the economy and industry: automotive, food, aeronautics, etc. To do this, the workshops use this machine tool that machines parts thanks to the action of a cutting tool called a milling cutter.

What are milling-machines?

The milling-machines are machine tools used for machining of parts per chip removal. This is possible thanks to the machine’s multi-edged rotary tool, which is the milling cutter. Through the operations performed in the milling machine, it is possible to shape pieces of different materials such as wood, steel, plastics, cast iron of iron and other metals. In addition, the pieces can have flat or curved surfaces. On the other hand, when the pieces have been milled, it is possible to subject them to other processes such as roughing.

CNC technology and universal-milling-machine-service

Before explaining what the universal milling service consists of, it is important to talk about CNC milling machines or computerized numerical control. Among the different types of milling machines that exist, CNC machines are a revolution for the industry, thanks to their great technology. These milling machines work exclusively through a computer; the machine’s computer is the one that indicates the cutting parameters that will be executed on a part.

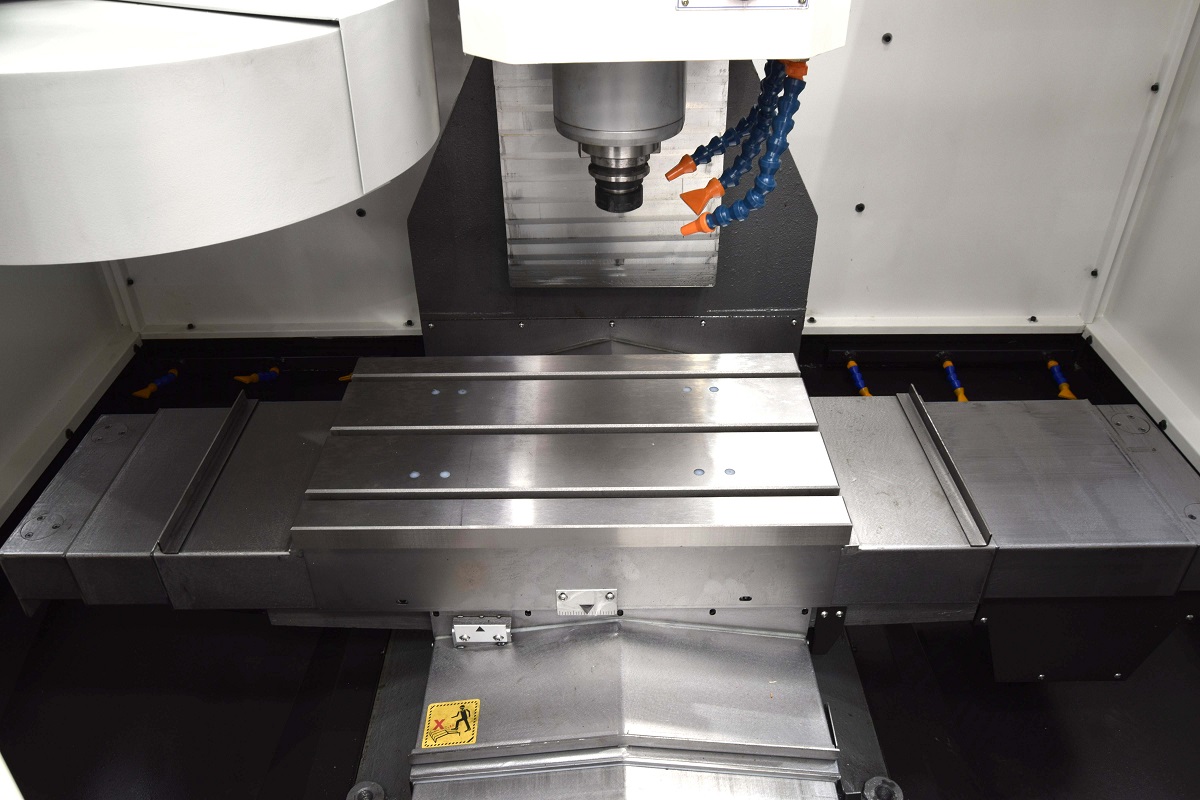

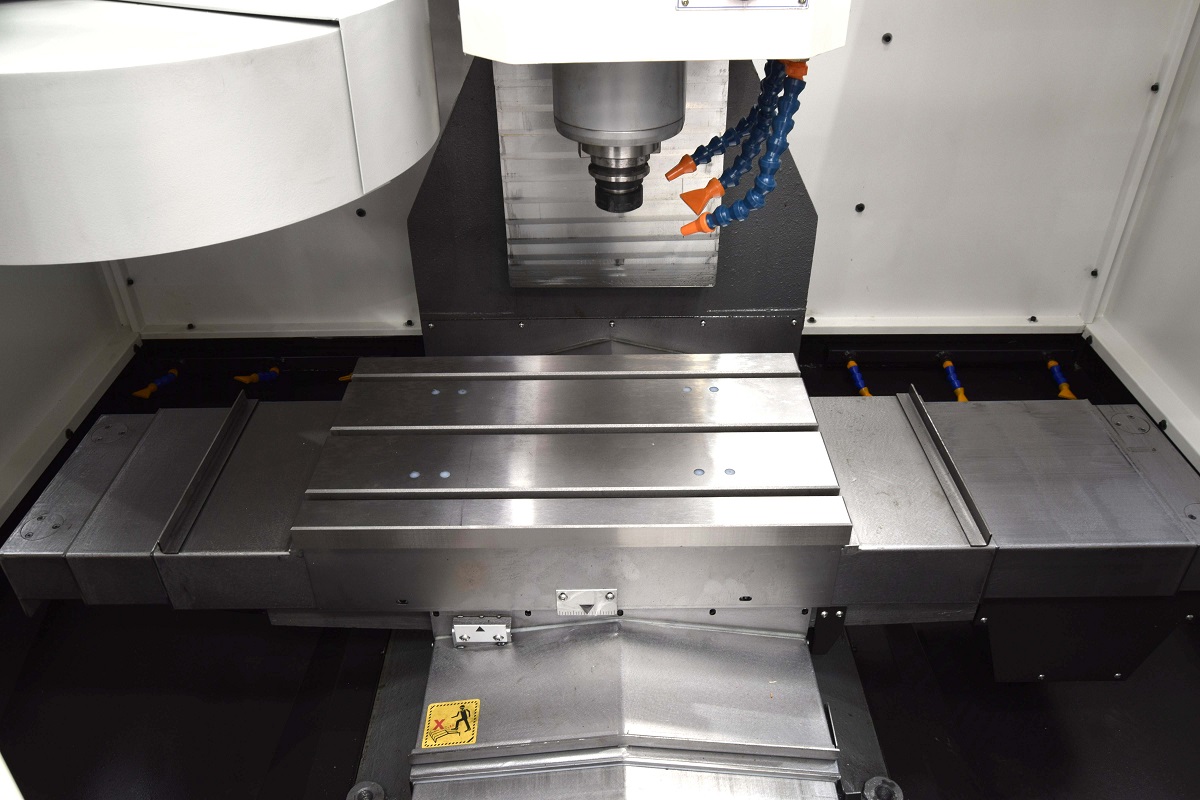

On the other hand, milling machines with these characteristics are equipped with a rotary milling cutter, provided with several cutting edges, which are the ones that They machine the part by approaching its surface. What distinguishes these milling machines from conventional ones? That the milling cutters rotate on the coordinate system of the machine and remove the excess material as they go.

In these machines, as in the rest of the machines that work with CNC technology, the part must be designed on external computers through software. computational CAD and CAM, which are design and computer-aided manufacturing. When the part has been designed, the results are uploaded to the machine’s computer and translated into alphanumeric CNC language.

What is the milling service?

The universal milling machine service refers to the set of operations that can be carried out on this machine tool, provided that it works by computerized numerical control. When talking about milling, we are talking about machining parts based on a coordinate system. The milling cutters receive these coordinates that are used to mark the cuts that will be made on the piece to be worked on.

This data is entered by the operator to the computer of the CNC machine in an alphanumeric language. Programming can be done manually, or one of the machine’s programs can be used. When the computer (CPU) receives the data, it is transferred through a controller to the main spindle of the milling machine. It is then that the parts (tools) of the milling machine receive the instructions of the movements they have to make (speed, feedrate and depth) to shape the piece.

The rapid movement of the cutter and of the edges that make it up allows for very fast machining. In addition, thanks to the fact that it is the computer that controls the processes, the results are much more precise, the surface finishes almost perfect and the piece is of great quality. On the other hand, machining is done in much less time, which means an increase in productivity, a reduction in production costs and labor.

Milling-machines with the most advanced technology

To provide auniversal milling service, as we have already mentioned, machine tools with the most advanced technologies are required. In this case, with equipment that works through computerized numerical control. In these devices, when the information is loaded, the CPU sends the instructions of what they have to do to the other components of the machine.

One of the advantages of these milling machines is that they are equipped with a tool holder in which multiple cutting tools can be placed. If the milling machine has the appropriate technology, the tool holder can rotate between the different tools needed to machine following different processes (milling, drilling, grooving , etc.).

The machines that have CNC technology are among the most used in industries such as food, automotive, aeronautics and aerospace. This is because CNC milling machines are capable of mass production, making parts of different dimensions (as small as a screw and as large as like the parts of an airplane), and machine complex and very precise parts from different angles. Hence, if you want a good universal milling service, you should look for a computer-operated machine tool.

Finally, it is important to note that CNC milling can be done on machines with different numbers of axes. The most advanced are those that can machine five axes. These move through the X, Y and Z planes, but also include A and B turning movements. These extra axes allow the machine to tilt the part and rotate it in such a way that the cutting tool can access it from different angles.