One of the most advanced machining techniques today is 5-axis machining . Thanks to this type of procedure, it is possible to machine pieces of different shapes and sizes that, due to their characteristics, cannot be worked on other machine tools . How does the 5-axis CNC work ? What machine tools have it?

What is 5-axis machining?

Before knowing how 5-axis CNC machining works , it is important that you know everything about this revolutionary technique that only brings advantages to the industry. This type of machining is named for the number of directions a machine ‘s cutting tool is capable of following . As you know, conventional machine tools can move in different directions , but on certain limited planes; for example, the lathe moves only on the X and Z planes , while the mill moves on the X, Y and Z axes . In 5-axis machining, two more are incorporated: A and B.

The A and B axes are actually turning movements that allow the cutting tool to access any angle and direction of the part to be machined. In reality, all machines, even if they are not 5-axis, can access any point on the part; the difference is that the part has to be repositioned manually, which is not the case with a CNC machine.

And it is that, that a 5-axis machine is CNC does not suppose more than advantages for the machining workshops. In other words, while in a conventional machine the operator has to reposition the part, the CNC machine does it automatically thanks to the A and B axes , depending on the work to be done on the part; this supposes a saving in production times.

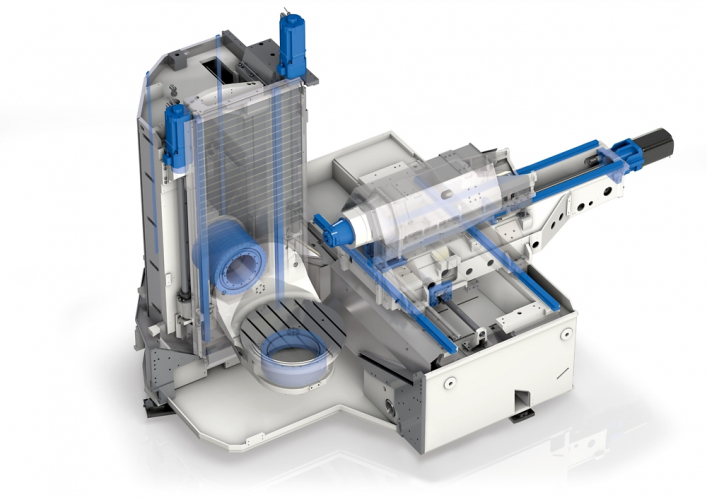

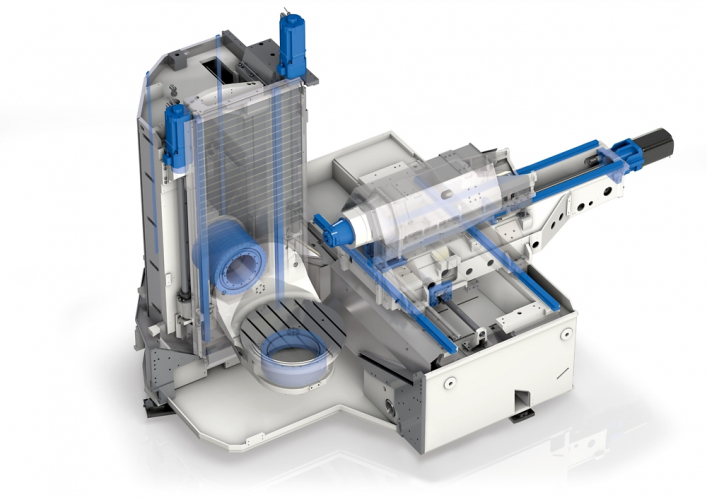

In conclusion, the 5-axis CNC machining is the one that allows to work, in a single time and without the need to stop the machine or reposition the part , the five faces of it. 5-axis machining is said to be one of the most advanced and complex techniques in the machining industry. The type of machining that follows is by chip removal and the movements can be done either by the work table or by the head.

multi-axis machining

It is important not to confuse the types of multi-axis machining . Although they are the most advanced work techniques and both have five axes, it is essential to learn to differentiate them. The types of multi- axis machining are:

- 3+2 machining. This type also includes the A and B axes , but these remain stationary , unlike the X, Y, and Z axes, which move simultaneously. Axis A and B can move, but when changing from one process to another.

- 5-axis machining. As we already anticipated, the 5 axes move simultaneously.

How the 5-axis CNC works: machining centers

Not all CNC machines machine 5 axes. This can only be done by specific machines called machining centers . These teams work in an automated way and are capable of performing multiple machining operations and work thanks to the CNC computerized numerical control. They require minimal human intervention and use rotary cutting tools; here the bits and cutters stand out.

How does the 5-axis CNC of a machining center work? This type of machine tools are capable of performing automated processes thanks to the CNC. Like the rest of machines that work by computerized numerical control, machining centers require additional programming software to be able to work on a part. Before placing the part on the machine platen , it must have been designed on external computers using CAD (computer-aided design) and CAM (computer-aided manufacturing) software. Once the part has been externally designed , this design must be translated into theCNC alphanumeric language and uploaded to the machine tool computer.

When the programming has been done (it can be done automatically or manually), the machining center can start to work. It is precisely thanks to the design loaded into the computer that the machine can know which cutting tools to use and how to position the part.

The movement of the axes

One of the features of the machining center is that it can machine all faces of a part at the same time. This is possible thanks to the 5 axes that compose it. The first three correspond to the Cartesian system X, Y and Z. Axes four and five are A and B, respectively. Axis A is used to control the rotation of the piece on any of the axes; the use of the A axis is ideal for machining cylindrical shaped parts .

For its part, axis B is in charge of providing the rotation mechanism of all the axes simultaneously. Thanks to the fifth axis , combinations of rotations can be created that provide greater movement; in addition, the B axis allows a perpendicular movement to be carried out on the axis, while the piece is tilted perpendicular to it.